The Moment of Terror Every Importer Knows Too Well

Picture this: After six months of development, your product finally arrives from China. You tear open the box with the excitement of a child on Christmas morning, only to find what appears to be your product's evil twin from a parallel universe where everything is slightly wrong. The blue is actually purple. The "metal" parts are suspiciously plastic-like. And that premium finish you specified? It has all the luxury feel of a gas station bathroom.

Congratulations! You've just experienced the special joy of international sourcing without a proper specification sheet. In the complex world of Chinese manufacturing, one document stands between success and writing off your entire inventory as an "expensive learning experience": the almighty Product Specification Sheet.

Why This Guide Isn't Just Another Boring Business Article

Unlike most advice that sounds like it was written by someone who's never actually imported anything more complicated than a pencil, this guide comes from the battle-scarred veterans of the sourcing wars. We've seen things. Terrible things. Products that arrived in colors that don't exist in nature. Packaging that disintegrated upon making eye contact. Materials so far from the original specification that they might as well have been harvested from alien planets.

So buckle up, because in 2025's complex manufacturing landscape, your spec sheet isn't just paperwork—it's your only defense against becoming another cautionary tale in the "Importing Hall of Horrors."

8 Critical Reasons Why a Spec Sheet Is Your Sourcing Lifeline (Or: How to Avoid Becoming a Business School Case Study)

1. Crystal Clear Communication (Because Telepathy Isn't a Business Skill)

Chinese factories aren't staffed by mind readers (we checked). Your vague request for something "like Apple but cheaper" will produce exactly what you deserve: a nightmare. A detailed spec sheet eliminates the guesswork, preventing those endless email chains where you slowly descend into madness typing "NO, NOT LIKE THAT" in increasingly larger fonts.

Think of your spec sheet as your product's universal translator in a world where "pretty good quality" can be interpreted in approximately 14,000 different ways.

2. Professionalism That Speaks Volumes (Or: How to Not Look Like an Amateur)

Top-tier Chinese manufacturers receive hundreds of inquiries weekly from people who think sourcing is just pointing at something on Alibaba and saying "I want that, but with my logo." A meticulously crafted spec sheet instantly separates you from the herd of dreamers and schemers who will never actually place an order.

When you send a proper spec sheet, you're essentially saying: "Hello, I am an actual business person who has done this before and not just someone who read a drop-shipping article on Medium last week."

3. Pricing Precision (Because "Good Quality" Pays Bills Said No Factory Ever)

In the absence of specifics, suppliers will default to the cheapest option possible—it's not personal, it's business. Your request for "leather" will get you something that once saw a cow on television. Your "stainless steel" might be aluminum painted silver with enthusiasm and prayers.

Without specific details, you're essentially telling suppliers: "Surprise me with your interpretation of quality! I love surprises, especially expensive ones that damage my brand's reputation!"

4. Rapid Supplier Screening (Or: How to Save Weeks of Talking to People Who Can't Actually Help You)

Want to waste months negotiating with factories that couldn't produce what you need if their lives depended on it? Of course not! A comprehensive spec sheet helps you quickly identify manufacturers capable of meeting your exact standards—whether it's ISO certification, FDA compliance, or the ability to produce something that won't spontaneously combust when exposed to air.

Think of your spec sheet as a time machine that fast-forwards through weeks of pointless supplier meetings.

5. Legal and Contractual Shield (Because "But I Thought You Understood" Isn't a Legal Defense)

Your spec sheet isn't just a document; it's legal body armor. As China Law Blog expert Dan Harris would tell you (probably while sighing deeply from experience), it becomes a critical component of contracts, purchase orders, and OEM agreements.

Without a detailed spec sheet, your legal position in a dispute has all the strength of wet tissue paper in a hurricane. With one, you transform from "disappointed customer with no recourse" to "business partner with enforceable expectations."

6. Quality Control Armor (Because Corners Will Be Cut If You Don't Nail Them Down)

Chinese manufacturers often operate on margins thinner than dollar store toilet paper. Without specifics, cost-saving "creativity" will find a way into your product. A detailed spec sheet leaves minimal room for such creativity, protecting your product from becoming an unintentional "budget version" of itself.

Remember: Every unspecified detail is an invitation to save money at your expense.

7. QC Inspection Blueprint (Or: How to Know If You're Getting What You Actually Paid For)

When your quality control team arrives at the factory (you do have quality control, right? RIGHT?), they'll use your spec sheet like a sacred text—checking every dimension, material, and tolerance with the precision of forensic scientists at a crime scene.

Without a detailed spec sheet, your QC inspection becomes as effective as trying to catch fish with a tennis racket.

8. Future-Proofing Your Product (Because Change Is Inevitable, Chaos Is Optional)

Need to modify your product next year? Want to switch manufacturers? Your original spec sheet becomes the perfect reference point, preventing the manufacturing equivalent of a decades-long game of telephone where your product gradually morphs into something unrecognizable.

Think of your spec sheet as a time capsule of what your product is actually supposed to be.

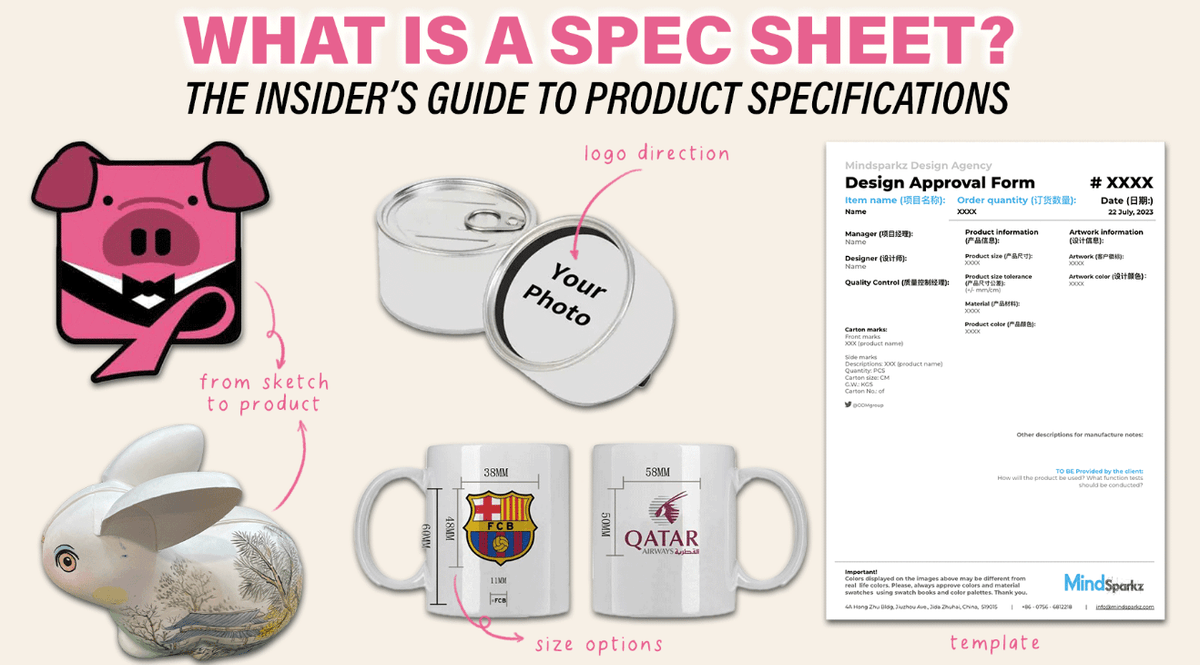

What Must Your Spec Sheet Include (Or: The "Leave Nothing to Chance" Checklist)

Comprehensive Spec Sheet Checklist (Pin This to Your Forehead If Necessary)

- ✅ Detailed Product Description - Not "water bottle" but "500ml double-wall vacuum insulated stainless steel water bottle with matte finish"

- ✅ Unique SKU Identifier - Because "the blue one" isn't specific enough when you have 47 products

- ✅ Precise Material Specifications - Including grade, thickness, and composition, because "metal" could mean anything from aerospace-grade titanium to something that might be aluminum if you're feeling generous

- ✅ Exact Product Dimensions - In both imperial AND metric, because nothing says "fun times" like discovering your manufacturer interpreted inches as centimeters

- ✅ Tolerance Limits - Because "approximately" isn't a measurement, and in manufacturing, close enough is rarely good enough

- ✅ Pantone Color Codes - Not "blue" or even "navy blue" but "Pantone 19-4021 TCX," unless you enjoy playing Russian roulette with your brand colors

- ✅ Mandatory Testing Requirements - Unless you enjoy surprise phone calls about product recalls or spontaneous meetings with regulatory authorities

- ✅ Pricing Parameters - Clear expectations for different quantity breaks, because "best price" is meaningless

- ✅ Order Quantity Ranges - From minimum order to forecasted annual demand, because factories price differently based on volume

- ✅ Label & Packaging Specifications - Down to the cardboard thickness and barcode requirements, because packaging is often the first thing to get "cost optimized" into oblivion

- ✅ Shipping Instructions - Because finding out your products have been packed for container shipping when you needed air freight is a special kind of pain

- ✅ Special Manufacturing Notes - Those crucial details that don't fit elsewhere, like "this part must be assembled by humans, not over-caffeinated octopi"

- ✅ Multi-Angle Product Photographs - Because one man's "rounded corners" is another man's "perfect circle"

Pro Tip for 2025: Cultural Intelligence Matters (Or: Why Your Email Isn't Getting Answered)

Remember, you're not just buying a product—you're building an international relationship across language barriers, time zones, and cultural expectations. In this context, your vague request for "good quality" makes about as much sense as asking someone to build you "a nice house" without any plans.

Cultural nuances and language barriers don't just make communication harder; they transform it into an Olympic sport where the rules keep changing and nobody told you what game you're playing.

Final Thoughts: The Spec Sheet Mindset

In the evolving landscape of global sourcing, a robust spec sheet isn't a luxury—it's the difference between telling the story of your successful product launch and explaining to investors why you have a warehouse full of unusable inventory that only vaguely resembles what you ordered.

Don't just source; source like someone who wants to stay in business long enough to place a second order.

Ready to transform your China sourcing approach?

Start with a killer spec sheet. Or don't, and join the illustrious club of business owners who have fascinating stories that begin with "So I thought I was clear about what I wanted..." and end with heavy drinking.

ChinafulLink Team: Because someone should benefit from all our expensive sourcing mistakes, and it might as well be you.