Why 1 in 3 Imported Products Fail Quality Inspection (And How to Protect Yourself Before You're Living in a Box Behind Your Warehouse)

Imagine receiving a shipment of products you've spent months planning, only to discover that 35% of them are fundamentally flawed. This isn't a nightmare scenario—it's the stark reality of importing from China in 2025, and approximately as pleasant as discovering your new swimming pool is actually a sinkhole with ambitious marketing.

Your beautiful product photos on Amazon? Meet their distant cousins: the actual products that just arrived. If they were people, they wouldn't be invited to the same family reunions.

The Quality Control Crisis: By the Numbers (Or: Statistics That Will Make You Reconsider Your Life Choices)

Recent quality control data reveals a critical warning for importers that's about as subtle as a fire alarm in a library:

- 81% of products from some Chinese provinces fail basic quality standards (roughly the same success rate as New Year's resolutions in February)

- Even the BEST regions have a 35% failure rate (better odds than a casino, but worse odds than most marriages)

- Critical defects could cost you everything: customer trust, reputation, and potentially legal challenges (or as lawyers call it, "job security")

These aren't just numbers—they're the difference between "successful entrepreneur" and "person who now explains to friends why they're selling their barely-used yacht."

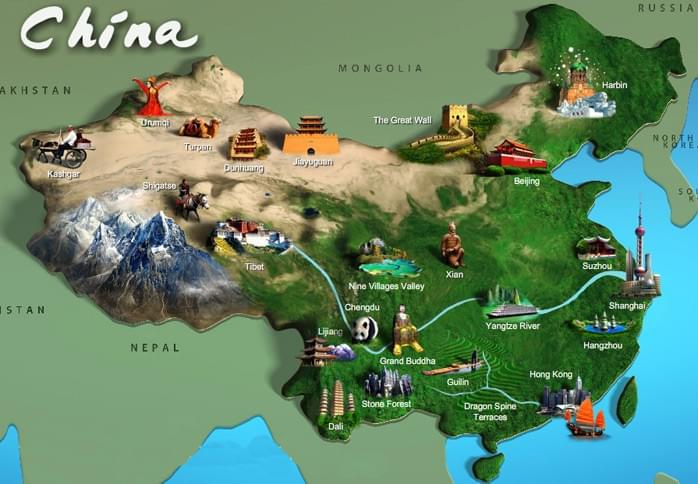

Understanding the Quality Landscape (A Geography Lesson That Could Save Your Business)

Regional Quality Variations (Because Location Matters More Than Your Dating Profile Claims)

Not all Chinese provinces are created equal in manufacturing quality. Some regions produce excellence, while others produce... well, let's call them "learning opportunities."

1. Top-Performing Regions (Where Manufacturing Dreams Come True-ish)

- Zhejiang Province: Home to manufacturing that occasionally makes German engineers nod in approval

- Guangdong Province: Where your products might actually resemble what you ordered

These eastern and southern provinces boast:

- More experienced workforce (people who've been making things since before TikTok existed)

- Advanced manufacturing techniques (beyond "hit it until it works")

- Higher quality control standards (they actually check if things work before shipping them)

2. High-Risk Regions (Where Your Products Go to Have Existential Crises)

- Shanxi Province: Beautiful landscapes, potentially questionable manufacturing

- Northern and Western Chinese provinces: Gorgeous places to visit, perhaps not to source your life-saving medical devices

Challenges include:

- Less manufacturing experience (still on the steep part of the learning curve)

- Lower skill levels (enthusiasm doesn't always equal expertise)

- Inconsistent quality control (ranging from "meticulous" to "looks good from far away")

Critical Quality Standards You Can't Ignore (Unless You Enjoy Late-Night Panic Attacks)

Acceptable quality limits are defined by three key metrics, which is manufacturing's way of saying "here's how bad things can be before we admit there's a problem":

- 0% Critical Defects: Absolute no-go (safety and regulatory compliance). Think products that catch fire when they shouldn't or toys with small parts labeled "choking hazard: collector's edition"

- < 2.5% Major Defects: Significant product issues that make customers write reviews in ALL CAPS

- < 4.0% Minor Defects: Slight specification variations that only you and that one obsessive customer will notice

Remember: The difference between a critical defect and a minor one is approximately the difference between "the brakes don't work" and "the cup holder is slightly off-center."

Protecting Your Import Investment: 5 Essential Quality Control Strategies (Or: How to Avoid Becoming a Business School Cautionary Tale)

1. Geographical Due Diligence (Because Geography Class Finally Becomes Useful)

- Prioritize suppliers in Zhejiang and Guangdong (the manufacturing equivalent of dating someone your mother would approve of)

- Research province-specific manufacturing capabilities (not all regions are equally skilled at everything—much like your attempts at cooking various cuisines)

- Remember: The 1,500 miles between Guangdong and some western provinces is also a time machine spanning decades of manufacturing advancement

2. Pre-Shipment Inspections (Trust, but Verify... then Verify Again)

- Never skip third-party quality control (it's like skipping the home inspection when buying a house—exciting until the first rainstorm)

- Conduct comprehensive product testing that goes beyond "yep, looks like a product"

- Use international inspection services who understand both Western expectations and Chinese manufacturing realities (cultural translators with clipboards)

- Remember: That sample they sent you was likely hand-crafted by their most skilled worker, possibly under direct supervision from the CEO's grandmother

3. Supplier Audits (The Manufacturing Equivalent of Meeting the Parents)

- Visit manufacturing facilities, preferably unannounced (surprise visits reveal more than carefully choreographed tours)

- Verify quality management systems beyond a certificate on the wall (preferably systems that don't include "hope for the best" as a key strategy)

- Build long-term relationships with reliable manufacturers (sending holiday cards optional but effective)

- Pro tip: If they won't let you see the actual production floor, consider this the manufacturing equivalent of your date not letting you meet any of their friends

4. Detailed Specification Documents (Because "Make It Nice" Isn't a Specification)

- Create crystal-clear product requirements that would make technical writers weep with joy

- Include precise quality benchmarks that don't involve subjective terms like "good" or "premium quality"

- Leave no room for interpretation or creative license (unless you're specifically in the "surprise me" business)

- The rule of thumb: If your specification document isn't longer than the last book you read, it's probably not detailed enough

5. Continuous Quality Monitoring (Because One-Hit Wonders Rarely Last)

- Regular random sampling (trust issues are healthy in international manufacturing)

- Consistent performance reviews that don't just happen when something goes wrong

- Adaptive supplier management based on actual performance, not promises or that nice dinner they bought you

- Remember: Manufacturing quality is like a garden—neglect it for a while and suddenly you're growing things you never planted

The Real Cost of Skipping Quality Control (A Financial Horror Story)

Without Inspection:

- Potential 35-81% product failure (approximately the success rate of DIY haircuts)

- Massive financial losses that make your accountant develop a nervous twitch

- Reputation damage that even the best PR firm can't fix ("But our influencer campaign was going so well!")

- Potential legal issues that make you wish you'd become a dentist like your mother wanted

With Professional Quality Control:

- Reduced risk (sleep through the night again!)

- Consistent product quality that doesn't vary more than your mood during tax season

- Customer satisfaction rates that don't resemble a ski slope pointing downward

- Business protection that's cheaper than the therapy you'll need without it

Take Action Now (Before Your Competitors Read This Article)

Don't become another cautionary tale in international importing—the kind that gets shared in business school classes with the lights dimmed and somber music playing. Invest in robust quality control and safeguard your business's future.

Remember: In the world of importing, "hoping for the best" is not a strategy; it's the prologue to an expensive lesson.

Ready to Optimize Your Import Strategy? (And Stop Having Those Recurring Nightmares About Defective Products)

Contact Our ChinafulLink Team Experts for a FREE consultation and quality control assessment. Because sometimes the smartest business decision is admitting you can't do everything yourself.

Note: No products were harmed in the writing of this article. The same cannot be said for businesses that skip quality control.