Why 1 in 3 Imported Products Fail Quality Inspection (And How to Protect Yourself)

Imagine receiving a shipment of products you've spent months planning, only to discover that 35% of them are fundamentally flawed. This isn't a nightmare scenario—it's the stark reality of importing from China in 2025.

The Quality Control Crisis: By the Numbers

Recent quality control data reveals a critical warning for importers:

- 81% of products from some Chinese provinces fail basic quality standards

- Even the BEST regions have a 35% failure rate

- Critical defects could cost you everything: customer trust, reputation, and potentially legal challenges

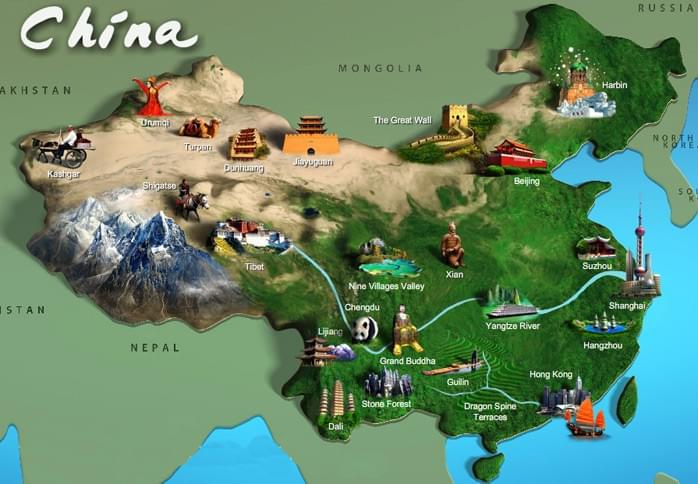

Understanding the Quality Landscape

Regional Quality Variations

Not all Chinese provinces are created equal in manufacturing quality:

1. Top-Performing Regions

- Zhejiang Province

- Guangdong Province

These eastern and southern provinces boast:

- More experienced workforce

- Advanced manufacturing techniques

- Higher quality control standards

2. High-Risk Regions

- Shanxi Province

- Northern and Western Chinese provinces

Challenges include:

- Less manufacturing experience

- Lower skill levels

- Inconsistent quality control

Critical Quality Standards You Can't Ignore

Acceptable quality limits are defined by three key metrics:

- 0% Critical Defects: Absolute no-go (safety and regulatory compliance)

- < 2.5% Major Defects: Significant product issues

- < 4.0% Minor Defects: Slight specification variations

Protecting Your Import Investment: 5 Essential Quality Control Strategies

1. Geographical Due Diligence

- Prioritize suppliers in Zhejiang and Guangdong

- Research province-specific manufacturing capabilities

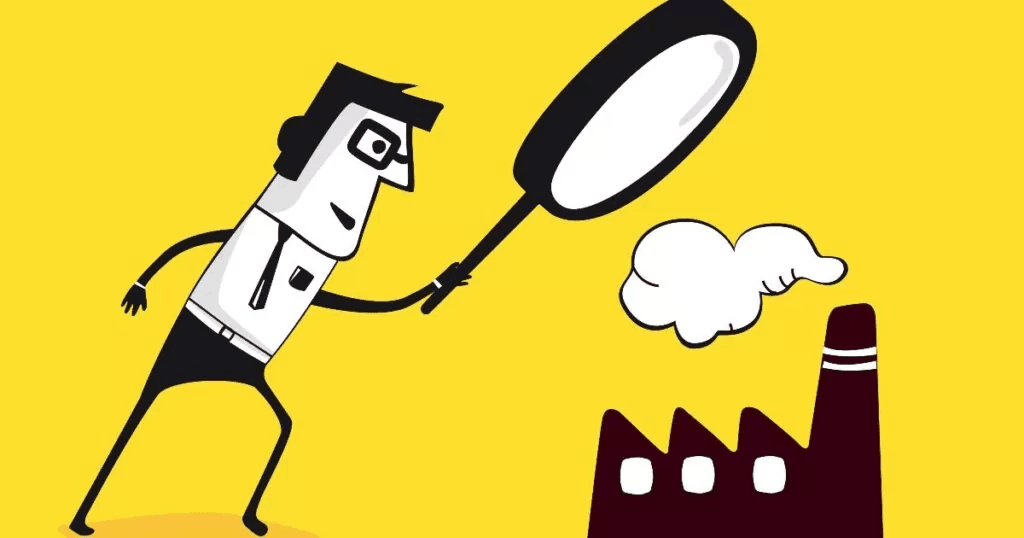

2. Pre-Shipment Inspections

- Never skip third-party quality control

- Conduct comprehensive product testing

- Use international inspection services

3. Supplier Audits

- Visit manufacturing facilities

- Verify quality management systems

- Build long-term relationships with reliable manufacturers

4. Detailed Specification Documents

- Create crystal-clear product requirements

- Include precise quality benchmarks

- Leave no room for interpretation

5. Continuous Quality Monitoring

- Regular random sampling

- Consistent performance reviews

- Adaptive supplier management

The Real Cost of Skipping Quality Control

Without Inspection:

- Potential 35-81% product failure

- Massive financial losses

- Reputation damage

- Potential legal issues

With Professional Quality Control:

- Reduced risk

- Consistent product quality

- Customer satisfaction

- Business protection

Take Action Now

Don't become another cautionary tale in international importing. Invest in robust quality control and safeguard your business's future.

Ready to Optimize Your Import Strategy?

Contact Our ChinafulLink Team Experts for a FREE consultation and quality control assessment.

Keywords: China imports, quality control, manufacturing, international trade, product inspection